IT’S ABOUT MAKING HANGOVERS GOOD FOR THE PLANET

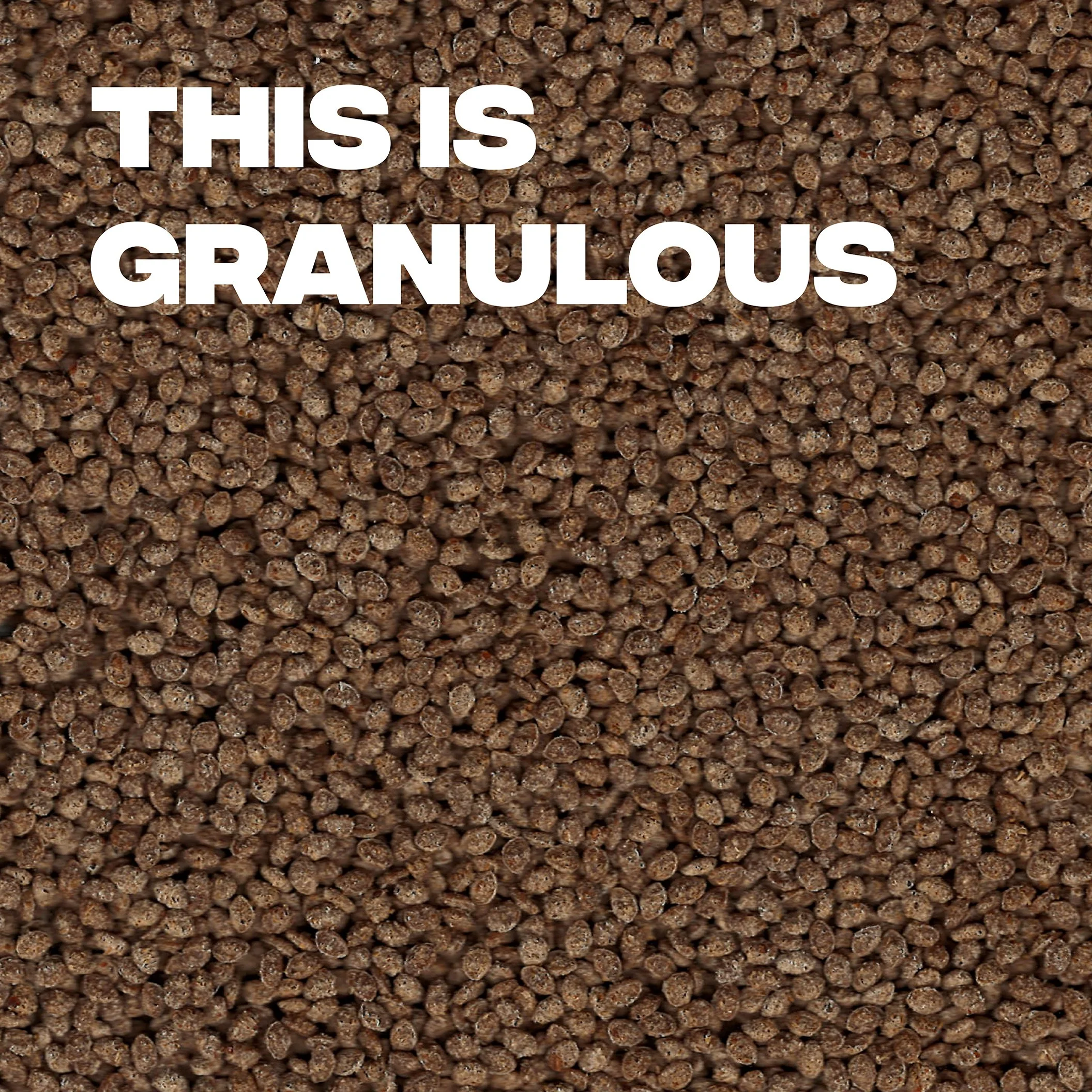

Every beer leaves a hangover behind—not in your head, but in the mountains of spent grain created during brewing. Most of it gets downcycled or wasted. We prefer a better recovery plan. Granulous takes the brewing industry’s leftovers and turns them into high-performance, bio-based materials that replace fossil plastics where it matters most.

Instead of plastics that stick around for decades, our materials do the job, then break down naturally—returning nutrients and organic matter back to the soil. The result? Products that perform in the real world, support healthier soil and leave no long-term mess behind.

So the next time someone enjoys a cold beer, there’s a quiet win happening in the background: less waste, less plastic, and a smarter materials loop that turns yesterday’s party into tomorrow’s progress. Same hangover. Much better outcome—for the planet.

SAVING THE PLANET ONE GRAIN AT A TIME

·

FROM BEER TO BETTER FUTURES

·

WE PUT THE CULT IN CULTIVATE

·

SAVING THE PLANET ONE GRAIN AT A TIME · FROM BEER TO BETTER FUTURES · WE PUT THE CULT IN CULTIVATE ·

FROM BEER TO BETTER FUTURES

-

BREWING INDUSTRY BY PRODUCTS

Every pint of beer creates nearly twice its weight in spent grain — rich in fiber and protein, but mostly used for animal feed or biogas.

We saw an opportunity here: instead of treating spent grains as waste, why not upcycle them into something with long-term environmental impact?

That’s where Granulous began.

-

TRUE COST OF "CHEAP" PLASTICS

We’re surrounded by plastics that’s cheap to produce—but expensive for the planet.

Cheap imported virgin plastic, often subsidised or produced under looser environmental standards, continues to flood global markets.

Even worse, some “recycled” plastic on the market is allegedly mislabelled or blended with virgin content, undermining trust and distorting the economics of genuine recycling efforts.

-

THE CIRCULAR STORY

What makes Granulous special is the circularity of the model.

It’s a perfect example of the bioeconomy in action:Beer is brewed → spent grain is created → we turn it into Granulous material → it’s used in agriculture → it composts back into the soil → growing the next generation of crops and, eventually, more beer.

It’s a closed loop — a simple, elegant cycle that connects food, farming, and sustainability.

-

IMPACT AND VISION

Our vision is clear: to replace fossil-based plastics in agriculture with bio-based, compostable alternatives that actually benefit the soil.

We’re scaling up production, expanding our partner network as we move into full commercialization.

But more importantly, we’re building a new materials ecosystem — one that’s circular, regenerative, and rooted in local resources.

SO WHAT SETS US APART?

While most plastics are fossil-based, brittle, and environmentally awkward, our material is tough, stable, and knows when to exit the stage. High impact resistance? Check. Low shrinkage and smooth processing for manufacturers who enjoy sleeping at night? Also check. It behaves beautifully in molding—unlike most “sustainable” materials that like to cause drama.

And then there’s the afterparty. In agricultural use, Granulous doesn’t just disappear—it improves the soil. Slow-release nutrients, happy roots, better soil structure, and well-fed soil life, all without burning plants or sneaking in nasty heavy metals. One recipe feeds plants, second strengthens soil and the third one is just Granulous —they all play the long game.

So yes, our materials are strong enough for industrial use, gentle enough for the soil, and smart enough to compost when their job is done. Not bad for something that started its life as beer waste. Turns out even leftovers can have a glow-up.

Next-Phase Investment OPPORTUNITY & Future Steps (2026/2027)

Granulous is entering its next phase of growth, and we are currently preparing an investment round for 2026/2027, aligned with our roadmap to scale into international markets and expand technological capability. Key areas of development in this phase include:

Polymerization technology for grain-based materials – enabling improved performance and new applications.

Utilization of fertilizers within our bio-material formulations – creating added value for the agriculture sector and circular-economy-based materials.

Expansion of collaboration projects across agriculture, viticulture, and horticulture – strengthening our pipeline with industry partners.

Localized production models and strategic partner networks – allowing regional scalability and reduced logistics footprint.

Join us as we turn beer waste into global impact. If you are interested to be part of Granulous’ next growth phase, fill up the form and tell us about your self.